Sometimes it just pays to be have a skillful team applying their resources to a mission they’ve accomplished dozens of times and that they utterly embrace. Customers in turn realize the benefit of developments in what has been for years the fast moving practice of intelligent design. Lately in fact, hospital construction has seemed to be advancing more rapidly than other sectors in commercial construction. At Guarantee Electrical Company, performing the dual role as electrical and communications systems contractor while providing the electrical design in this environment of what seems like particularly rapid changes for the better, has proved to be especially fortunate. Because, it’s clear that something new is afoot as progress on construction of SSM Health® St. Louis University Hospital has advanced faster and with fewer changes than could have been expected any time prior to this particular moment in construction history.

realize the benefit of developments in what has been for years the fast moving practice of intelligent design. Lately in fact, hospital construction has seemed to be advancing more rapidly than other sectors in commercial construction. At Guarantee Electrical Company, performing the dual role as electrical and communications systems contractor while providing the electrical design in this environment of what seems like particularly rapid changes for the better, has proved to be especially fortunate. Because, it’s clear that something new is afoot as progress on construction of SSM Health® St. Louis University Hospital has advanced faster and with fewer changes than could have been expected any time prior to this particular moment in construction history.

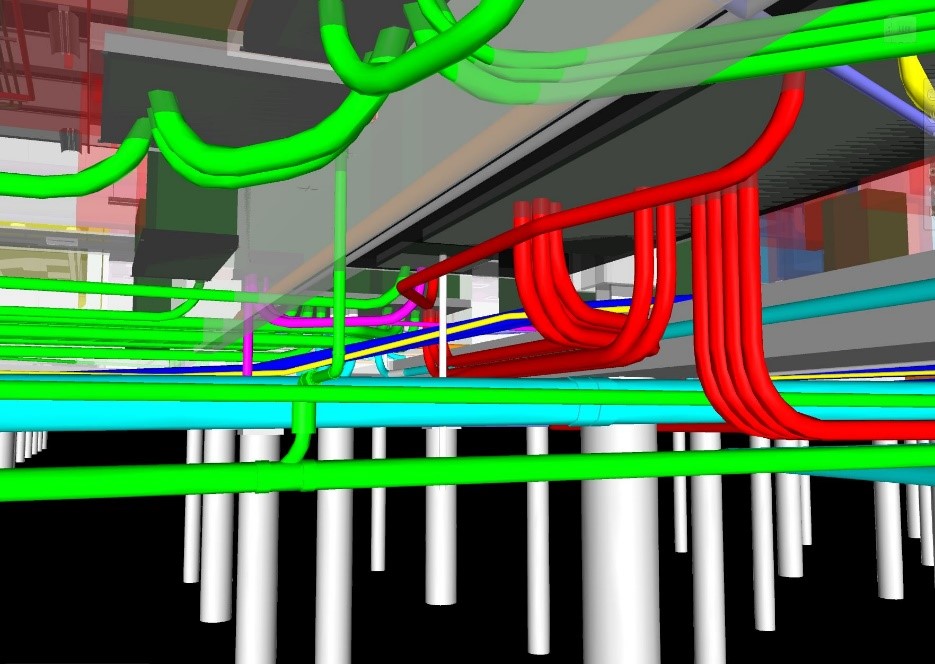

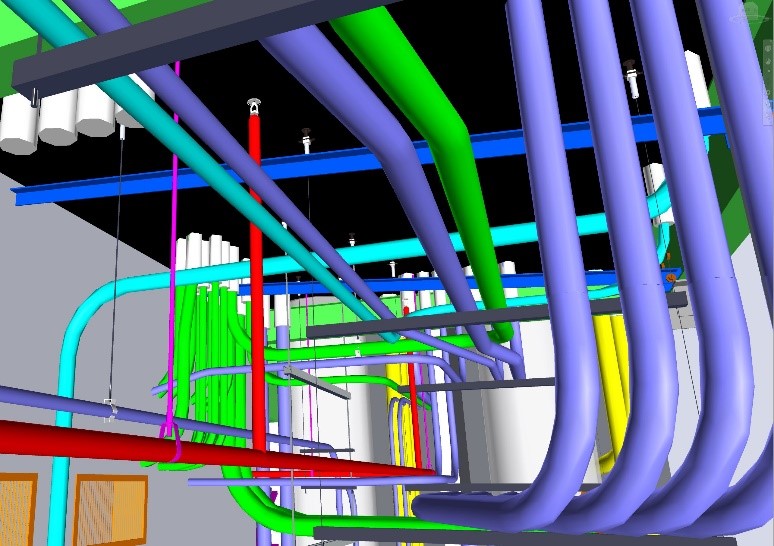

No question, much of this has resulted from Building Information Modeling (BIM) and Virtual Design and Construction (VDC) and their impact on how hospitals in particular are constructed these days. Equally important—and absolutely related—is the ability to visualize in 3-D, the pathways of information concerning every kind of constituent material and componentry has brought new ways of staging the processes of construction. In the current environment, craftsmen are able to coordinate in new ways with other specialists as well as with architects and engineers. It used to be that trades like mechanical, electrical, and plumbing kept to their own silos, pursuing their specialties happy to stay out of one-another’s way.

And in some ways, they still do. Only now because modeling enables the trades to visualize their work in 3-D over time, leading to new approaches to collaborating and not just avoiding conflicts and clashes. For example, building out-patient rooms used to involve painstaking custom processes which involved installing by turns a range of components and services, many essential or even life-saving. Now with BIM coupled with rapidly evolving practices of prefabrication, two and even three trades can achieve highly repeatable levels of quality with precise installations. Now electrical outlets, data drops, medical gas piping, and a host of sensors, can all be “custom” installed to meet specific treatment requirements for rooms whose headwalls are predesigned then prebuilt offsite, in Guarantee Electrical Company's 15,000sf prefabrication center, for just-in-time delivery, and fitted exactly into place much more quickly and efficiently. Additionally, by utilizing BIM, Guarantee Electrical Company has the ability to pre-bend conduit of all sizes in the prefabrication center and ship on trucks rather than using benders on the jobsite, thereby reducing jobsite clutter and hazards. Add to this, new types of templates and wall covering materials and construction of patient rooms/treatment spaces moves faster and more efficiently than ever, frequently at lower cost.

just avoiding conflicts and clashes. For example, building out-patient rooms used to involve painstaking custom processes which involved installing by turns a range of components and services, many essential or even life-saving. Now with BIM coupled with rapidly evolving practices of prefabrication, two and even three trades can achieve highly repeatable levels of quality with precise installations. Now electrical outlets, data drops, medical gas piping, and a host of sensors, can all be “custom” installed to meet specific treatment requirements for rooms whose headwalls are predesigned then prebuilt offsite, in Guarantee Electrical Company's 15,000sf prefabrication center, for just-in-time delivery, and fitted exactly into place much more quickly and efficiently. Additionally, by utilizing BIM, Guarantee Electrical Company has the ability to pre-bend conduit of all sizes in the prefabrication center and ship on trucks rather than using benders on the jobsite, thereby reducing jobsite clutter and hazards. Add to this, new types of templates and wall covering materials and construction of patient rooms/treatment spaces moves faster and more efficiently than ever, frequently at lower cost.

Now, as SSM Health® St. Louis University Hospital is building out diverse floors of highly specialized services (from Level 1 trauma care to advanced cancer therapies) together with floors dedicated to SLU’s highly prized standards of patient-centered care, the ability to design-build healthcare spaces dense with technology can’t be over-valued. For electrical and communications services, the ability to deliver forms of customization utilizing highly repeatable process management techniques, plays very favorably, as administrators and treatment specialists seek “best-of” solutions to accelerate construction and perfect their new facility. Indeed, because medical technology advances as rapidly as it does, designing-in extra capacity for future adaptability will be invaluable to administrators and practitioners who need to manage change ever more rapidly and more effectively.

Indeed, because medical technology advances as rapidly as it does, designing-in extra capacity for future adaptability will be invaluable to administrators and practitioners who need to manage change ever more rapidly and more effectively.

In detail, SSM Health® SLU Hospital’s Ameren 5KV feeds run from an adjacent manhole up into two basement level electrical rooms, where five unit substations step the power down to 480V. Two additional substations, fed from two parallel 2000KW generators, supply emergency power. Four bus-duct risers distribute power up the patient tower. Each floor is outfitted with sets of satellite panels, providing the 120V normal and critical power, and a dedicated UPS panel in each tele/data room. Each of the hospital’s 17 operating rooms are supplied with two separate power panels, respectively for normal and critical power.

Distribution continues by way of risers feeding the first floor emergency department, exam and physician rooms, and on to and through a second level devoted primarily to the mechanical systems supplying all important sanitary and temperature controlled air and supported by networked building systems automation. Note that modeling branch distribution, as well as the data conduit supplying electrical and systems infrastructure, involved mapping and optimizing distribution across the hospital’s multiple levels, including two wings of a patient tower running from floors three to eight, capped by a penthouse housing additional mechanical systems. In addition, conduit had to be labeled to identify four forms of segregated power (serving life safety, critical, equipment and normal requirements) as well together with data cabling. Together, these supply some 35 plus imaging rooms mapped by floor and treatment/diagnostic requirements, that spanned the range of imaging technologies for MRI, radiology, PET and CT scanning, ultrasound and fluoroscopy, etc.

mechanical systems. In addition, conduit had to be labeled to identify four forms of segregated power (serving life safety, critical, equipment and normal requirements) as well together with data cabling. Together, these supply some 35 plus imaging rooms mapped by floor and treatment/diagnostic requirements, that spanned the range of imaging technologies for MRI, radiology, PET and CT scanning, ultrasound and fluoroscopy, etc.

Bottom line, expanding on St. Louis University’s century-plus tradition as a center of academic medicine, with its new $550 million, 316-bed, 802,000-square-foot SSM Health® St. Louis University Hospital will deepen its reputation as an American College of Surgeons (ACS) certified Level 1 Trauma Center. More importantly, as it combines advanced academic medicine with leading-edge treatment and research focused on patient centered care, the new combined facility will fully integrate with the adjacent Saint Louis University School of Medicine along with the world-class pediatric center at nearby SSM Health Cardinal Glennon Children’s Hospital.